Machineries for Resource Conservation

Machineries for Resource Conservation

Prem K Sundaram, Sanjay K Patel and S C Sharma

Human society has developed by utilizing our planet’s resources. Different natural resources like soil, water, and air help in the growth of plants. As the population of the world is increasing at an alarming rate, the consumption of natural resources is also increasing. Hence, these resources should be conserved to maintain ecological balance and save them for future generations.

There are different technologies that help in resource conservation in agriculture. Few are listed below:

| Sr. No | Resource Conservation Technologies | Resource Conserved |

| 1 | Bed planting of crops | Water |

| 2 | Residue management | Water, soil quality |

| 3 | Laser land levelling | Water |

| 4 | Drip irrigation | Water |

| 5 | Unpuddled transplanting | Water, soil quality, air |

| 6 | Alternate wetting and drying | Water |

| 7 | Direct sowing of rice in puddled field through drum seeder | Water, human power |

| 8 | Direct sowing of rice zero tillage | Water, human power |

| 9 | Integrated farming system | Water, soil quality |

| 10 | Solar pumps | Water, energy |

| 11 | Crop sowing by zero tillage | Water, fuel, human energy |

| 12 | Biogas plants | Fuel |

| 13 | System of Rice Intensification | Water |

| 14 | Crop diversification | Water, soil quality |

| 15 | Reduced tillage | Water, soil quality |

| 16 | Stubble mulching | Water, soil quality |

There are different machines that help in the conservation of natural resources. They are briefly discussed below.

- Laser land leveler: In irrigated and rainfed environments, precision land leveling improves the uniform application of water, betters the crop stands and enhances the survival of young

Fig.1 Field leveling by laser land leveler seedlings and robustness of the crop to withstand stress. Laser-controlled grading technology (Fig. 1) is currently the best method to grade a field. The system includes a laser-transmitting unit that emits an infrared beam of light that can travel up to 700 m in a perfectly straight line. The second part of the laser system is a receiver that senses the infrared beam of light and converts it to an electrical signal. The electrical signal is directed by a control box to activate an electric hydraulic valve. This hydraulic valve raises and lowers the blade of a grader to keep it following the infrared beam. The receiving system detects the beam and automatically guides the machine to maintain proper grade.

- Seed drill/Seed cum fertilizer drill: The main function of the seed drill is to make a small furrow and then place the seeds in the opened furrow and after that, covers them with the soil. This machine works in tilled soil conditions. Drilling requires less quantity of seeds when compared with broadcasting, hence saving of 20-50 percent seeds. Seed cum fertilizer drill has an additional attached fertilizer box that places fertilizer also in the soil. Hence, seed cum fertilizer drill not only saves seed and fertilizer but also fuel and time.

- Zero seed cum fertilizer drill: This is specialized sowing equipment (Fig. 2) with an inverted “T” type furrow opener. It opens a narrow slit in the soil (Fig. 3) and seed, as well as fertilizer, are placed inside it. Zero tillage reduces tillage to only one pass. It allows timely sowing, which raises yields and lowers costs by saving soil, fuel, tractor costs, water, fertilizer and herbicides.

Fig. 2 Zero Seed sum fertilizer drill working in the field Fig. 3 Narrow slit in the soil by furrow opener - Happy seeder: The Happy Seeder technology offers a solution to the problem of direct drilling into heavy stubbles, enabling the stubble to be retained on the surface as a mulch. It combines stubble mulching and seed drilling function into one machine (Fig. 4). Flail type straight blades are mounted on the straw management rotor which cuts the standing stubbles/loose straw coming in front of the sowing tine for proper placement of seed in the soil. The rotor blades/flails guide/push the residues as surface much between the seeded rows. The soil is not disturbed in this process (Fig. 5). The stubble is then deposited behind the machine as a surface mulch. The mulch assists in retaining organic matter and moisture content of the soil. The surface mulch is broken down and incorporated into the soil by natural biological process over time. This PTO driven machine can be operated with 45 hp tractor or more and can cover 0.3-0.4 ha/h. The happy seeder is not only able to reduce the practice of stubble burning but also improves /retains the quality of soil, saving time, fuel and energy.

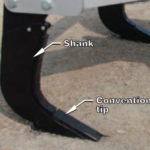

Fig. 4 Wheat sowing by Happy seeder Fig. 5 Wheat sown field by happy seeder 5. Subsoiler:Subsoiling is an important component of vertical tillage and is designed to eliminate the compaction created by horizontal tillage tools such as sweeps and shovel implements. It is a crucial process in conservation tillage which minimizes soil surface disturbance without inversion while shattering subsoil structure.

Fig. 6 (a) Winged type Subsoiler Fig. 6 (b) conventional Subsoiler A subsoiler is a tractor-mounted implement used for deep tillage, loosening and breaking up soil at deeper depths. Most tools like moldboard ploughs, disc harrows, or roto-tillers/rotavators will break up and turn over surface soil to a depth of 15–20 cm, whereas a subsoiler will break up and loosen the soil to twice those depths, i.e. up to 30-40 cm. A higher power tractor above 50 hp is required to operate it. It breaks the compacted layer of the soil which helps in increasing the infiltration capacity of the soil. The winged type subsoiler (Fig. 6a) is more useful than the conventional one (Fig. 6b) as it covers/caters more soil volume; however, it requires more power.

6.Super Seeder: Super Seeder is a combination of Rotary Tiller & Seed Planter with press wheels (Fig. 7a). It is extensively used for planting a wide variety of seeds like wheat, soybean & grass. The main function of the Super Seeder machine is to plough standing paddy stubble in soil and sow wheat seed simultaneously in a single operation after the harvesting of the paddy with combine harvester having Super-SMS attachment. It has a simple and easy metering system that allows the changing of seed varieties with less seed waste. It can be used for sowing other crops throughout the year including maize, pulses and can also be used only for ploughing purposes. The machine mixes standing paddy stubble of 12 to 18 inches into the soil and then sows the seed of wheat is sown 2-3 deep inches with it (Fig. 7b). Also, it cuts down the consumption of seed by about 10 percent.

Fig. 7a Super Seeder in combine harvested field Fig. 7b Wheat sown by super seeder in straw covered soil 7.Drip irrigation System: Drip irrigation also known as trickle irrigation system delivers water to the crop using a network of pipes known as mainlines, sub–mains and lateral lines with dripper/emitter points spaced along their lengths. The rate of water dropping into the soil is 2-20 liter per hour depending upon the crop, soil type and weather condition. Emitter works at low pressure (0-1 bar). From the drippers the droplets of water drop in the soil leading to maintain the soil moisture content. This irrigation system is most suited for horticultural crops (Fig. 8a & b), spices and forest crops. The fertilizer can also be delivered to the crop through the dripper points. The use of drip helps in saving water and nutrient. It saves water up to 70% as compared to flood irrigation. The fertilizer use efficiency is also increased up to 30 percent. Using drip as a source of irrigation can optimize the cost of production of crops drastically.

Fig. 8a Drip irrigation system in Papaya Fig. 8b Drip irrigation system in Potato 8. Sprinkler irrigation system: It is a method of applying irrigation water which simulates rainfall. The water is applied under high pressure with the help of a pump through a small diameter nozzle. With the selection of nozzle sizes, operating pressure and sprinkler spacing the amount of irrigation water required to fill the crop root zone can be applied nearly uniformly at the rate to suit the infiltration rate of the soil. The water-saving due to sprinkler system varies from 16 to 70 % over the traditional method with a yield increase from 3 to 57 % in different crops and agro-climatic conditions.

Resource Conservation technologies are the future of sustainable agriculture. It has direct impacts on farmers’ family as it reduces labour requirements for tillage, land preparation and weeding.

Dr Anil Kumar Singh

Very informative and very useful to farmers